Tips and Tricks in the Workshop

Presented by Nigel Dunstone from Rivelectric, this is a short photo journal covering some ideas and methodologies that can help you in your workshop.

Motors are Heavy

Safety in the workshop is paramount. This is what happens if you place your hand a 150kg motor as it is being lowered into place. Note the sixteen pins across one of the joints. It isn't just about the pain and medical cost, it is about the loss of time to the business. Your skilled employee is now off work recovering.

Calculation Matrix (to be updated)

Quite often you will need to replace windings of one wire diameter with another, it is really handy to have the key parameters multiplied out. It is far easier and saves more time, looking up up a quick chart than it is to sit there with a calculator, multiplying out the numbers to see what equivalent you can replace.

Having these calculations also reduces mistakes.

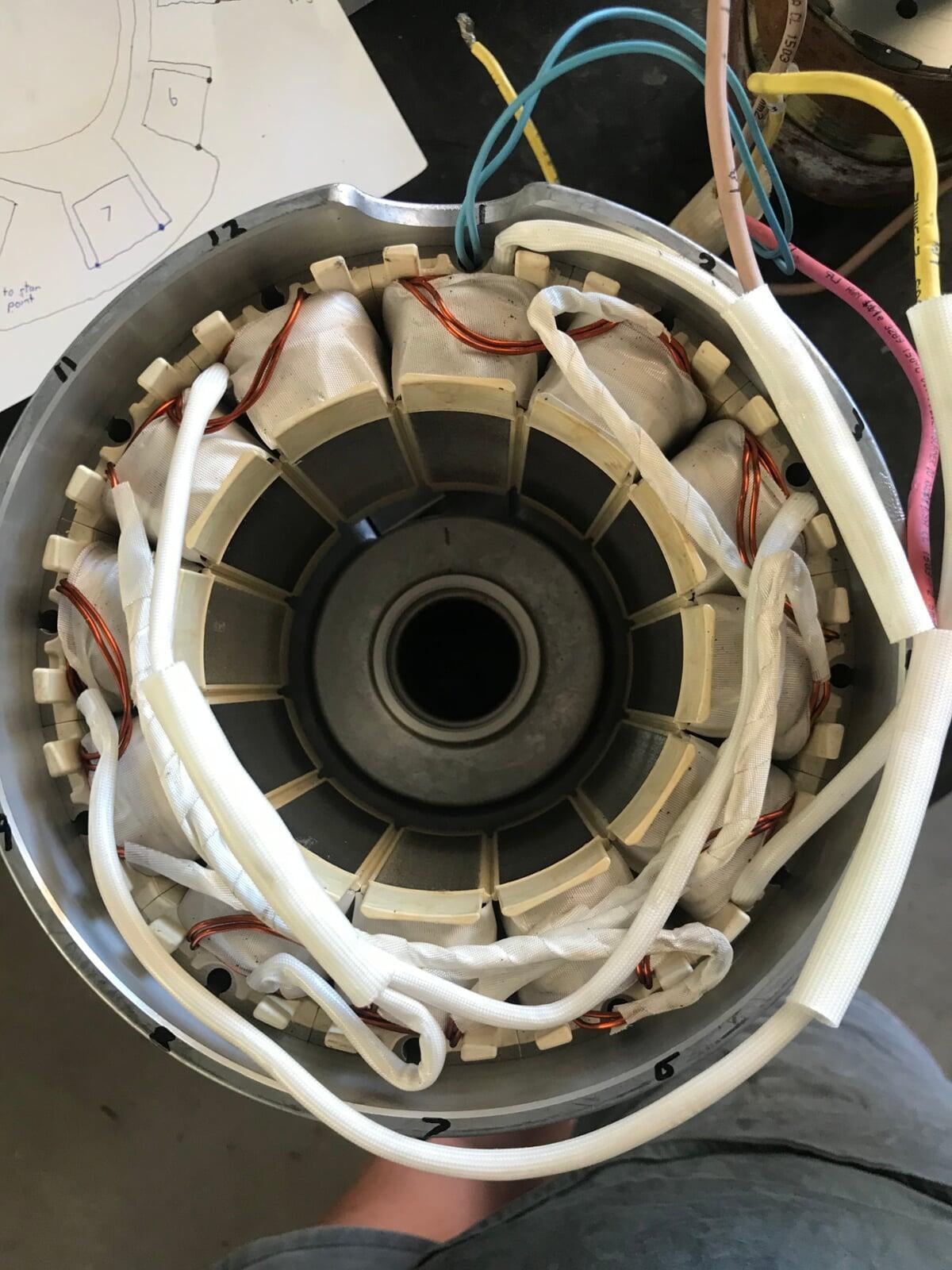

Repairing a Sludge Pump

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.

Wiring Issues

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.

Ok, what should we name this section

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.

400HP motor slot. The motor was tripping out intermittently.

The hole in the slot wedge was 8mm, a microscope revealed the damaged wire.

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.

Detailed description for this photograph.